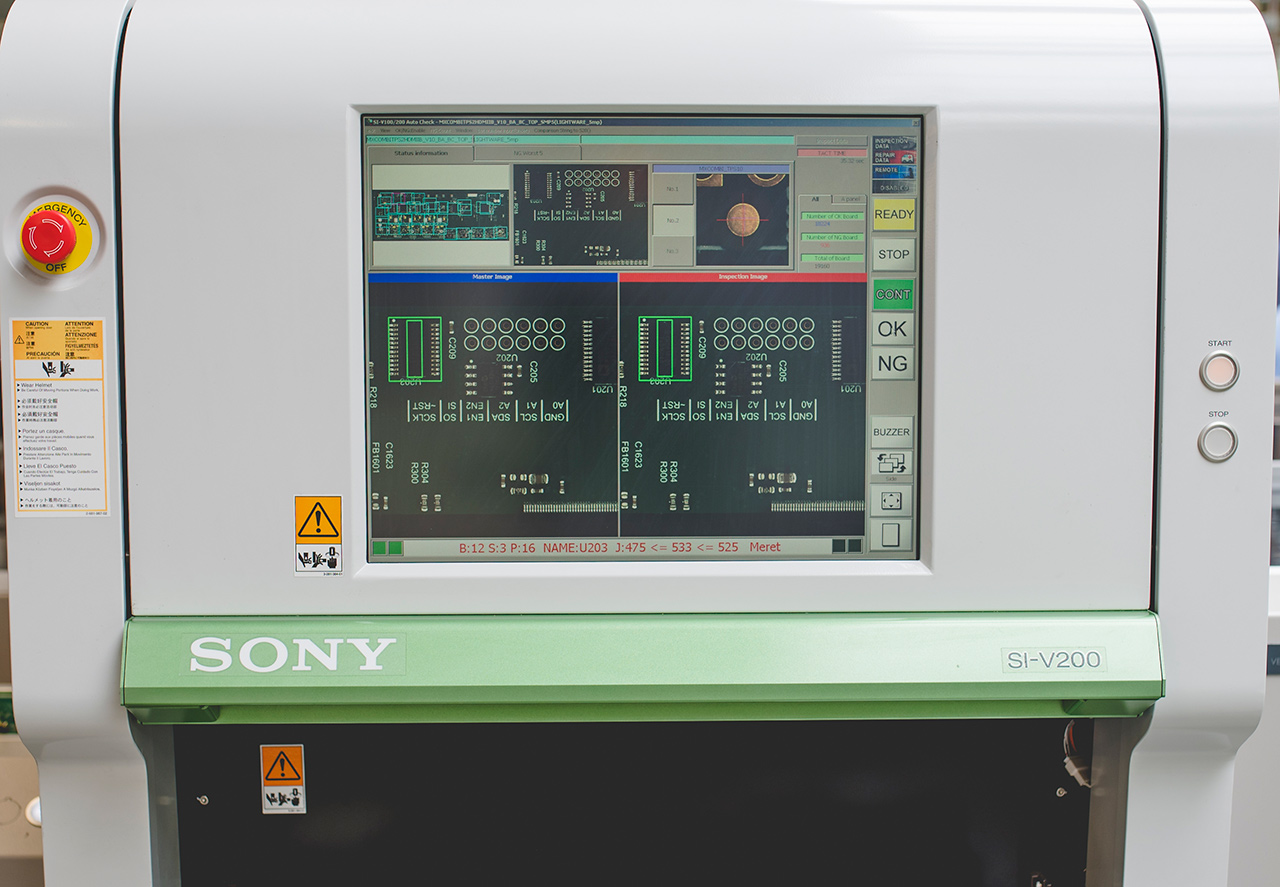

Visual Inspection Using Japanese Technology – AOI (Automatic Optical Inspection)

You do not want to receive faulty components, right? The third test phase, AOI, is carried out using cutting edge Japanese technology: In this phase, we are able to demonstrate or detect soldering anomalies, short-circuits, missing components, components with reversed polarity, or even a component that is situated slightly skewed.

The AOI system controls the unloader at the end of the production line, deposits passed products on the good(G) storage magazine, those assumed defective are placed into the not good(NG) storage magazine. The AOI indicates the faults to our colleagues working at the service department, who will examine parts rated NG. In case the part is actually defective, we intervene in the production process, but in some case AOI qualifies good components as defective, meaning that its programming requires alteration. No matter what, the result is the same: our facility produces perfect components assembled to comply with the plan requirements. Pictures taken are archived upon request and we provide FTP access for our partners for viewing.

The AOI system controls the unloader at the end of the production line, deposits passed products on the good(G) storage magazine, those assumed defective are placed into the not good(NG) storage magazine. The AOI indicates the faults to our colleagues working at the service department, who will examine parts rated NG. In case the part is actually defective, we intervene in the production process, but in some case AOI qualifies good components as defective, meaning that its programming requires alteration. No matter what, the result is the same: our facility produces perfect components assembled to comply with the plan requirements. Pictures taken are archived upon request and we provide FTP access for our partners for viewing.