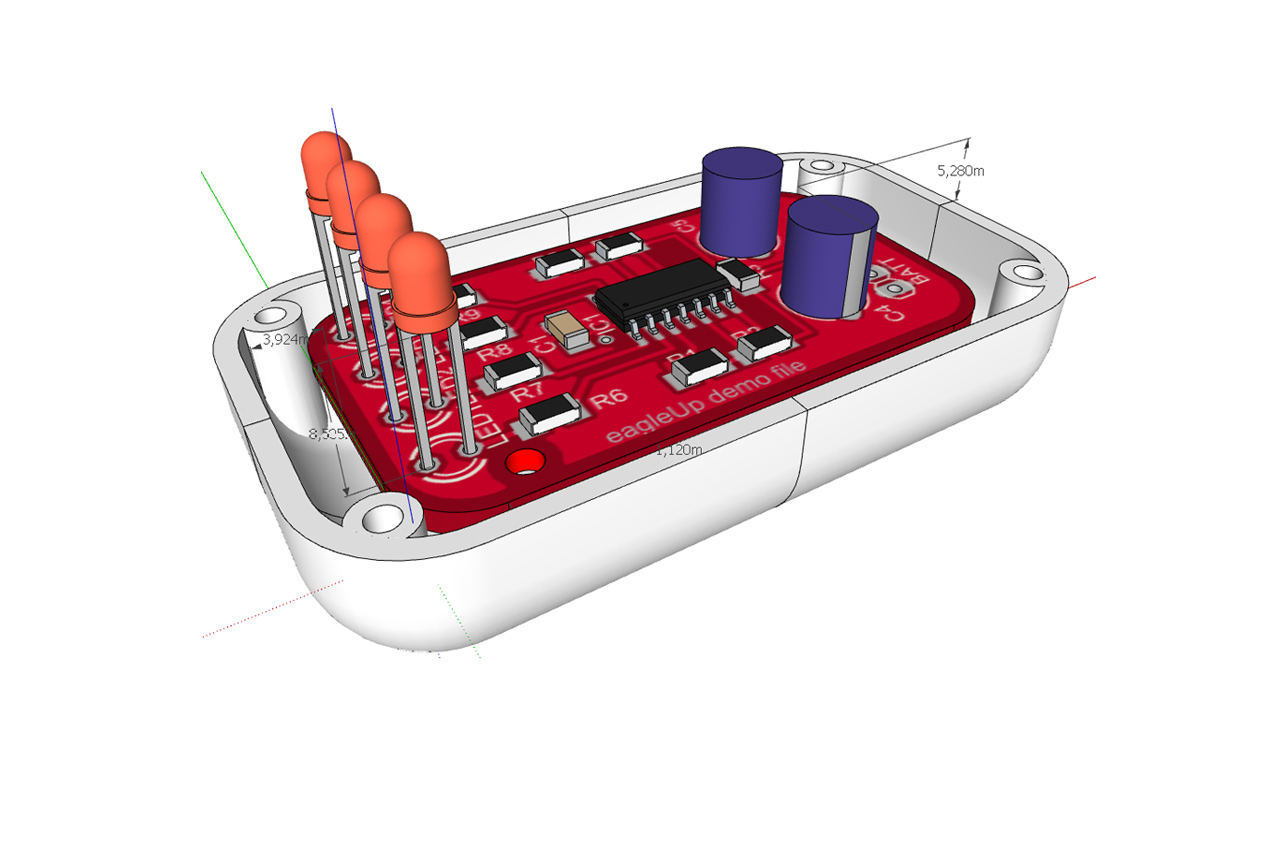

Validation Before Production – DVP (Design Validation Production)

Play it safe before initiating production: You design it, and we make sure that you know whether it is viable. In cases where we find any issues with manufacturability, we notify you before serial production and consult with you, if necessary.

Why is manufacturability control important? Even the most professional designers happen to make mistakes in taking manufacturability aspects into account. In such cases, there is a chance that the number of items on the component list do not match the designs received, or some components do not fit the way it was intended at the design phase because of sizing differences.

Why is manufacturability control important? Even the most professional designers happen to make mistakes in taking manufacturability aspects into account. In such cases, there is a chance that the number of items on the component list do not match the designs received, or some components do not fit the way it was intended at the design phase because of sizing differences.

This is why we introduced DVP (Design Validation Production): we manufacture a small number or prototypes before serial production, to shed light on any manufacturability issues or difficulties. In this phase, all components go through visual and instrumental inspection. If we discover any anomalies, our expert engineers will make suggestions to the designers for modification. With this feedback, we support our partners which manufacturing products of even higher quality.

Is it important for you not having to take unnecessary steps and initiate manufacturing processes that may cause substantial damage to you and your company?

Learn more about the second phase of testing! Or request a free quote now: